Using billions of experimental data to safeguard each infrared laser lighting module

Quality's the king: Using billions of experimental data to safeguard each infrared laser lighting module

In the spring of 2024, several new types of IR laser lighting module from 3KM Optoelectronics will be launched one after another. There is no one in the optoelectronic reliability laboratory, only the equipment for various reliability experiments that is busy 24 hours a day. It is now rare to see colleagues in the experimental group, as busy as before.

If it were in the usual way, it would be frustrating for colleagues in the reliability testing team.

Because before each new IR laser lighting module starts mass production, it must undergo three consecutive months of high and low temperature, high humidity and heat shock cycle testing. With just one IR laser lighting module, millions of experimental data must be recorded.

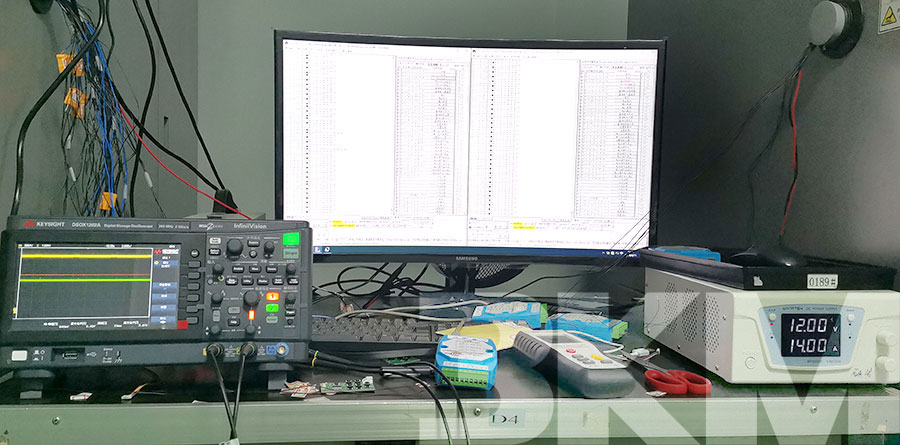

Fortunately, the company launched a self-developed fully automated control experimental system at the end of last year. It can not only monitor the experimental data of dozens of IR laser lighting modules in multiple experimental equipment at the same time, but also accurately record every instruction data and every millisecond of operation of each IR laser lighting module.

Now, the focus of the experimental group's work has shifted from statistical analysis of massive data to data analysis and causal investigation. Their ultimate goal is to eliminate the quality hazards of each IR laser lighting module before mass production, to ensure that the pass through rate of any IR laser lighting module during mass production can reach 100%.

The one we are seeing now is a high-temperature test. The maximum working temperature of the IR laser lighting module that we normally promise is+85 ℃. However, for some military products with quality requirements, we often increase it to+90 ℃, or even 100 ℃ for high-strength testing to ensure that the reliability of the product is not only to meet customer requirements, but also to exceed customer expectations. The current high-temperature test has been continuously tested for over 500 hours.

To achieve the goal of prioritizing product quality, we need to do ordinary work that is extraordinary! And this is precisely the cultural pillar flowing within the 3KM Optoelectronics.

Using billions of experimental data to safeguard each infrared laser lighting module video